DUNLOP OIL AND MARINE | HOSE TESTING SYSTEM

DUNLOP OIL AND MARINE

HOSE TESTING SYSTEM

Dunlop Oil and Marine are the leading specialist supplier of floating hoses for offshore transfer of crude oil and gas, and are part of the Continental ContiTech group. We have completed a number of design projects for Dunlop involving special purpose equipment, including a Mandrel Extraction Machine (MEM) and a Reeling Hose Test Rig (RHTR).

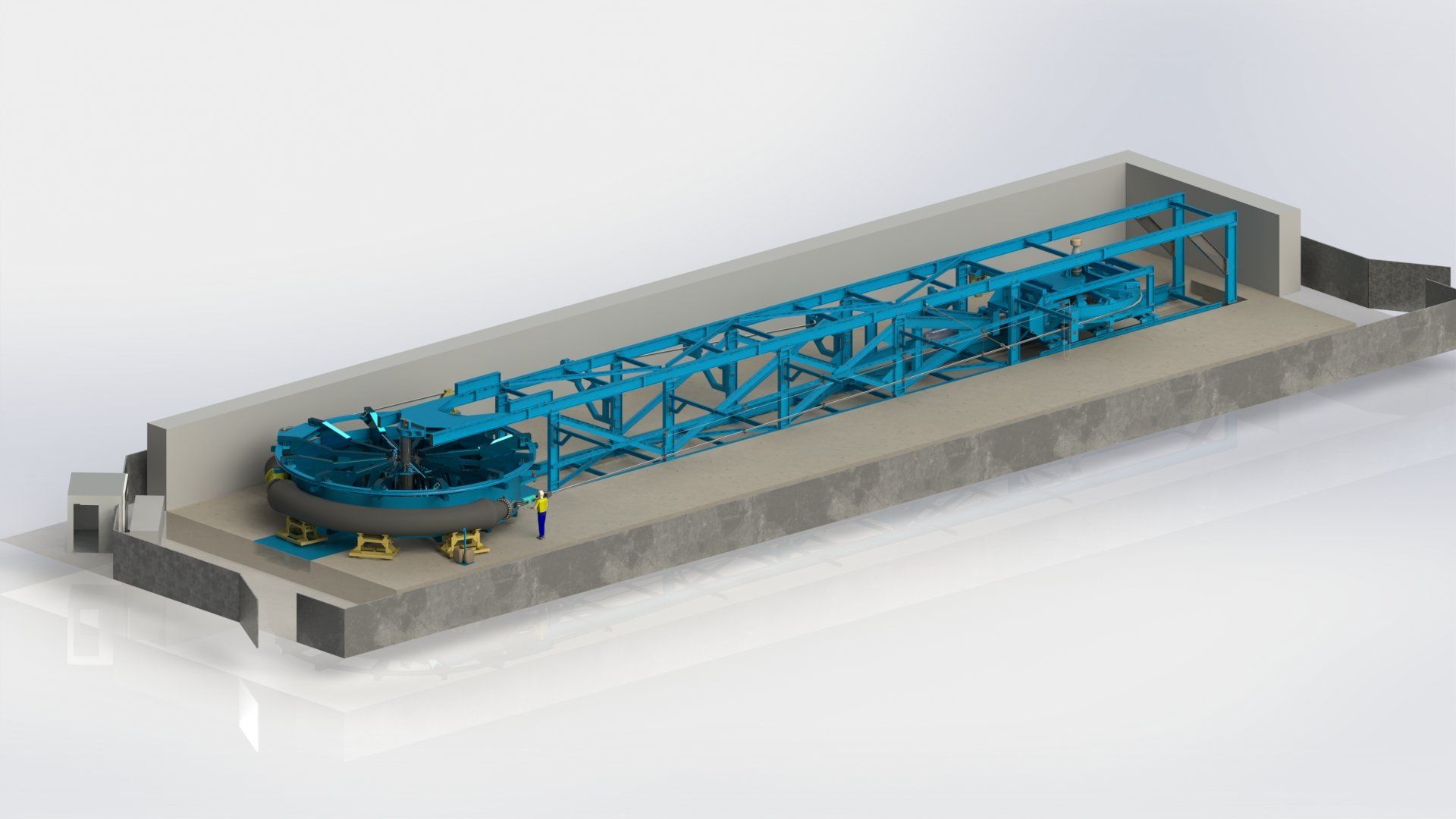

The RHTR brief was to design and develop a means of simulating the effect of repeatedly reeling and unreeling a hose onto a drum, under operational tension and internal pressures.

An initial feasibility project was undertaken to look at different ways of simulating operational conditions, and evaluate the best and most cost effective solution. Following successful completion, a design specification was produced by Chelker and we initiated a design project for the test rig.

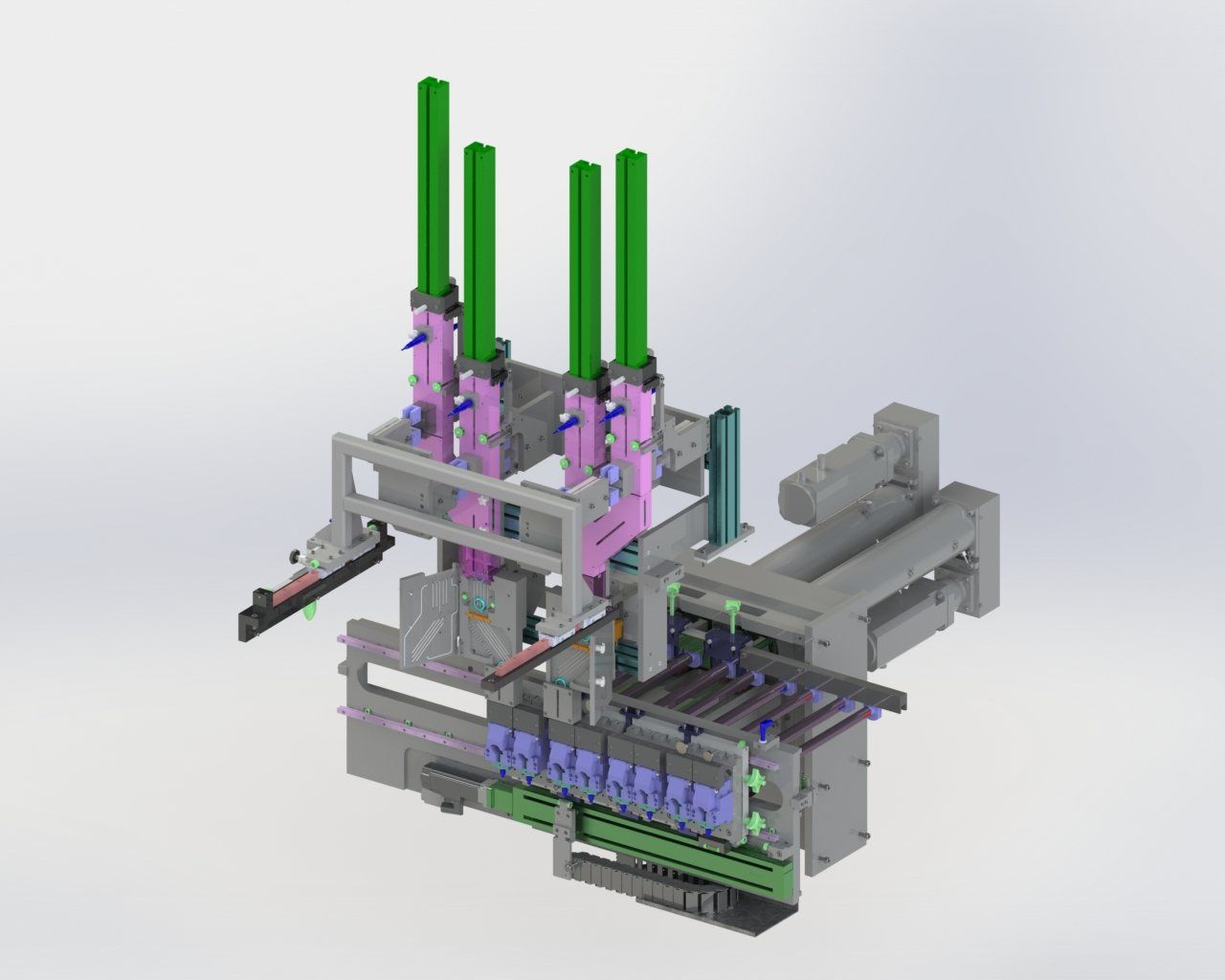

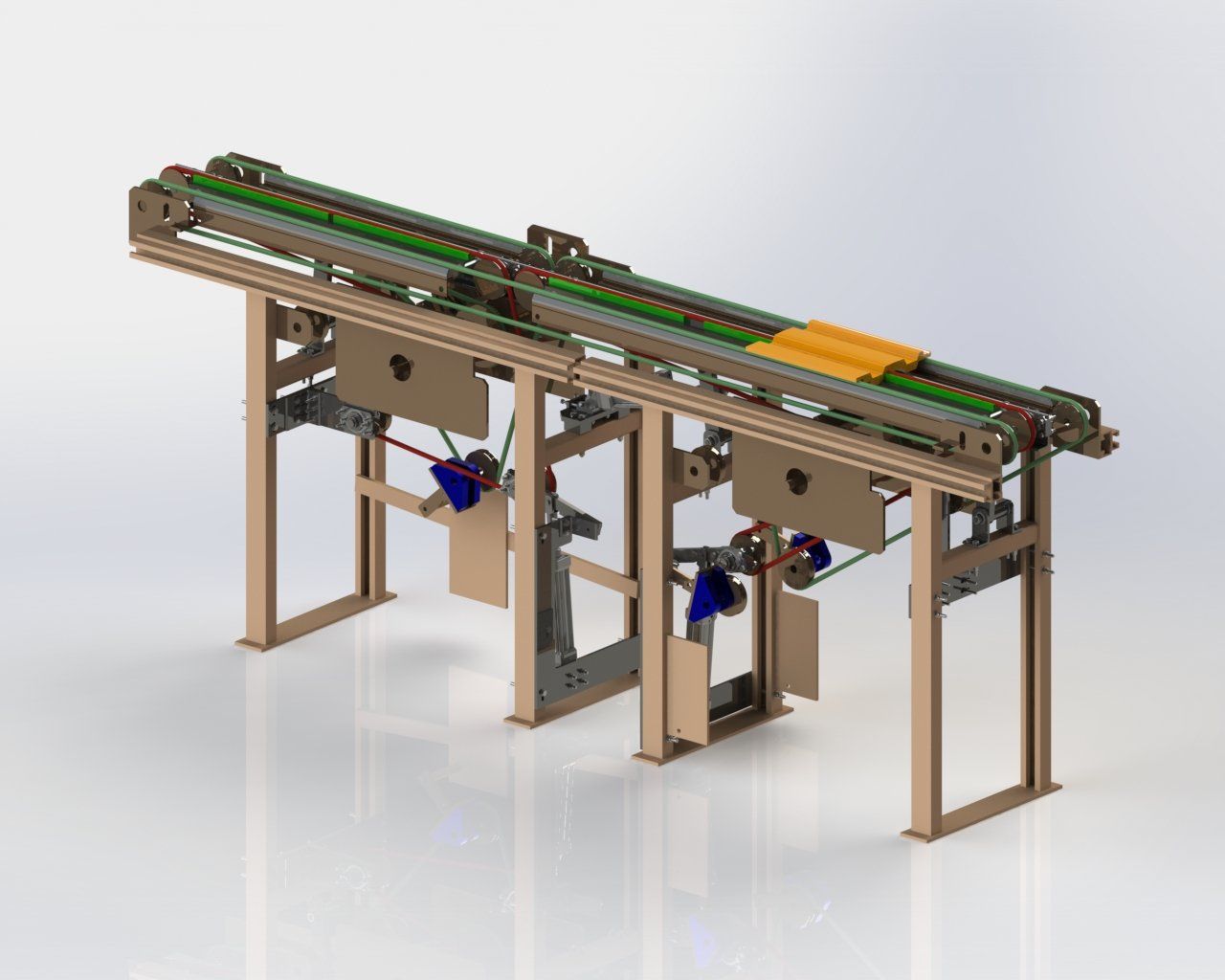

The equipment was fully designed and costed and detailed manufacturing drawings and parts lists were delivered to Dunlop. Documentation included stress analysis of various aspects of the rig using FEA, structural engineering reports of the frame and drum, foundation design (carried out by our structural engineering partners), hydraulic control system design, transducer selection, transducer integration, data logging, cable management, and safeguarding.

The final system was 36m long with a 9m diameter reeling drum, capable of testing hose strings up to 1.1m in diameter and 25m in length under a 60 tonne tensile load.

Finite Element Analysis