Reducing your manufacturing overheads

Automation & Special Purpose

With a wealth of experience in special purpose machine design and automation projects, we regularly save companies money by introducing appropriate levels of automation to their manufacturing processes. Working closely with our partners, we can offer everything from manual assembly fixtures to fully robotic manufacturing cells.

Chelker offer innovative, cost effective solutions that work well when you get them onto the shop floor, and I wouldn’t hesitate to recommend them.

CRAIG FLETCHER

Project Engineer, 3M UK

AUTOMATION AND SPECIAL PURPOSE

CASE STUDIES

3M

WINDING AND EDITING MACHINE

NORBAR

TUBE FEEDER

PROCANICAL

ROBOT TOOLING

3M

Winding and Editing Machine

3M is a global manufacturing company operating in 70 countries with almost 90,000 employees worldwide and 18 locations in the UK. Chelker supplies engineering design services and special purpose automation equipment to the company, working with their Project Engineers on diverse process improvement and automation projects.

“I have worked with Chelker Technology on several automation projects over the past few years, from process improvements to full machine design and supply. They have consistently shown that they can tackle a variety of engineering problems, by applying wide experience and unmatched professionalism. On a number of occasions they have worked to extremely challenging timescales and yet have still been able to provide excellent solutions for projects.

Notable projects have been;

– An improved rotary screen printing module

– A reel to reel winding and editing machine

– An ergonomic mixing station machine

Chelker offer innovative, cost effective solutions that work well when you get them onto the shop floor, and I wouldn’t hesitate to recommend them.”

CRAIG FLETCHER

Project Engineer

3M UK

NORBAR

automatic tube feeder

Norbar are a British manufacturing company who are world leaders in the design and manufacture of torque wrenches. As part of a major production improvement project and new manufacturing cell, Chelker were asked to design and supply automation to feed tubes from a magazine into a subsequent machine.

An early concept design was modified when the customer added a new requirement to feed non-round tube. The project followed our standard design project model in accordance with BS7000, creating an agreed design specification with change controls, and using this document during design reviews with the customer to ensure that their needs were met by the equipment.

Chelker manufactured and installed the machine alongside our manufacturing partners, receiving very positive comments from the customer regarding reliability and build quality. The machine was fully documented, risk assessed, safeguarded and CE marked by Chelker.

“In 2014 my team found itself in need of an automatic tube feeder similar to ones that feed CNC lathes but with a significant change in operation. After talking to the industry I was recommended to have a bespoke device made and Chelker’s name was given.

I made contact and after seeing some excellent proposals from the young design team we placed an order, for 60% of the cost of a standard unit.

We visited for design reviews twice, one to approve the concept design and another to witness detailed design and to visit the fabrication shop. The final visit was a de brief after the pre delivery trial.

This machine was delivered and continues to perform very well. When a component failed Chelker’s response was swift and comprehensive. This is a fine engineering business.”

ALAN COLLINS

Process Manager

Norbar Torque Tools Ltd

PROCANICAL

ROBOT TOOLING

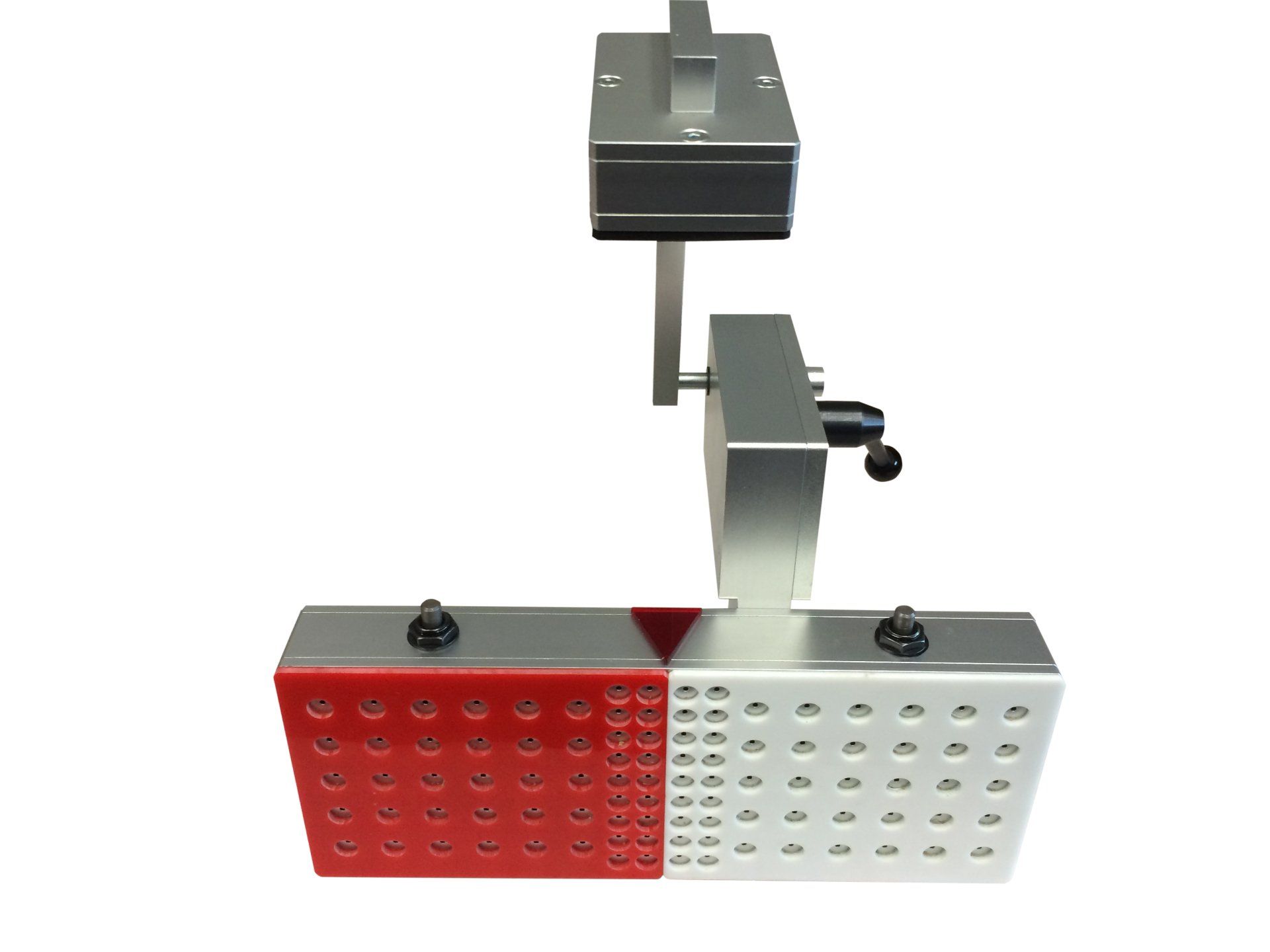

Procanical Ltd are a specialist robot tooling company based in Blackburn, Lancashire, but servicing industry throughout the UK. Procanical work with major robot suppliers and system integrators such as Yaskawa Motoman, Kuka, ABB and Kawasaki. They design and manufacture specialist multi-task tooling and robot grips for product handling.

Chelker have worked with the Procanical team since 2004 supplying mechanical design, manufacturing drawings and parts lists for a variety of cross industry projects including automotive, food packaging, foundry handling, furniture assembly, and component manufacturing.

The automation shown here is for project C5410. Chelker provided a full mechanical design from concept to detailing for this robot tooling. The task was for palletising dairy products presented by roller conveyor. The multi-purpose grip was required to pick from between the conveyor rollers, accurately place the product in the correct pattern, and also place interleaf sheets between layers.